What is plunge EDM?

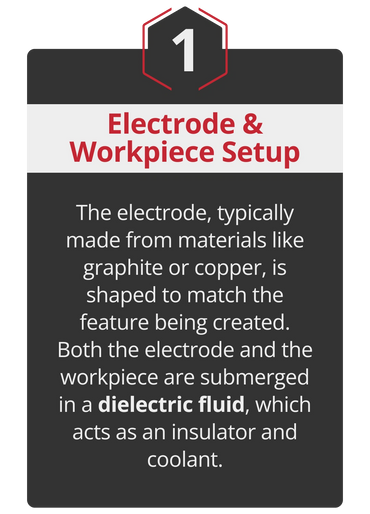

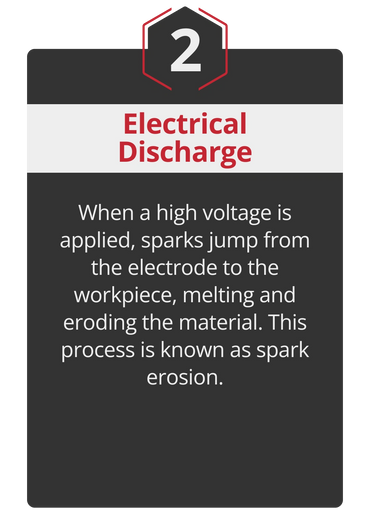

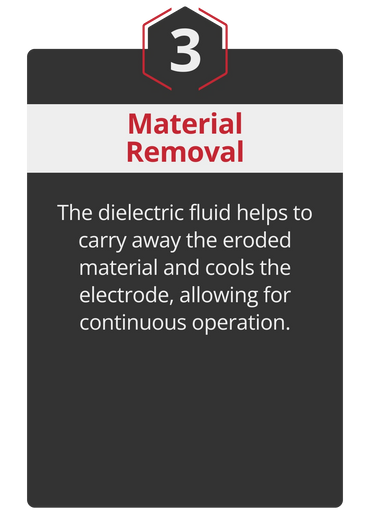

Plunge EDM, also known as sinker EDM, is a specialized form of electrical discharge machining (EDM). This process is used to create intricate shapes and cavities in conductive materials by using electrical discharges (sparks) between an electrode and the workpiece. The electrode is designed to match the desired shape of the cavity, and it "plunges" into the material, hence the name.

How Plunge EDM Works

Applications of Plunge EDM

Plunge EDM is particularly useful for creating complex shapes that are difficult to achieve with traditional machining methods. Common applications include:

- Mold making: For injection molds and other tooling.

- Creating blind cavities: Such as keyways and internal splines.

- Precision parts: Used in Petrochemical, aerospace and medical devices where tight tolerances are required.

Pros & Cons of plunge EDM

CONTACT US ABOUT YOUR SINKER/PLUNGE EDM NEEDS

Plunge EDM is a powerful tool in modern manufacturing, especially for industries that require high precision and the ability to work with hard materials. If you have specific applications or materials in mind, we can provide more tailored information!

Copyright © 2025 trinityedm.net - All Rights Reserved.

Your Partner in Precision Metal Cutting